How booster pumps work and where they are typically used

2024-05-08

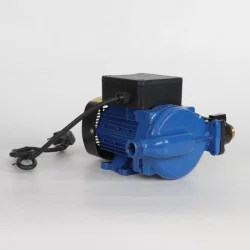

Booster pumps are essential components used to increase water pressure in residential, commercial, industrial, and agricultural settings. They are commonly employed in situations where the existing water pressure is insufficient to meet the demands of the application. Here's how booster pumps work and where they are typically used:

1. How Booster Pumps Work:

- Booster pumps operate by drawing water from a low-pressure source, such as a municipal water supply, well, or storage tank.

- The pump then pressurizes the water and delivers it to the desired location at a higher pressure.

- Booster pumps can be either centrifugal or multistage pumps, depending on the required pressure increase and flow rate.

2. Applications:

- Residential: Booster pumps are often used in homes to increase water pressure for showers, faucets, and irrigation systems, especially in properties with low municipal water pressure or gravity-fed systems.

- Commercial and Industrial: They are used in commercial buildings, hotels, hospitals, and industrial facilities to ensure adequate water pressure for firefighting systems, HVAC systems, manufacturing processes, and other applications.

- Agriculture: Booster pumps are employed in agricultural irrigation systems to deliver water to crops at the required pressure and flow rate, improving irrigation efficiency and crop yields.

- Municipal Water Distribution: In some cases, booster pumps are installed in municipal water distribution systems to boost water pressure in areas with low-pressure zones or during peak demand periods.

3. Types of Booster Pumps:

- Single-Stage Centrifugal Pumps: Suitable for applications where moderate pressure increases are required, such as residential and light commercial settings.

- Multistage Centrifugal Pumps: Ideal for applications demanding higher pressure boosts, such as high-rise buildings, industrial processes, and large-scale irrigation systems.

- Variable Speed Booster Pumps: These pumps feature adjustable speed settings to precisely control water pressure and flow rates based on fluctuating demand, offering energy efficiency and optimized performance.

4. Considerations:

- Flow Rate and Pressure Requirements: Select a booster pump that can meet the desired flow rate and pressure requirements of the application.

- Installation Location: Consider the available space, piping layout, and electrical requirements when selecting a booster pump and determining its installation location.

- Energy Efficiency: Choose energy-efficient booster pumps with variable speed controls or other energy-saving features to minimize operating costs and environmental impact.

- Maintenance: Regular maintenance, including inspection, lubrication, and cleaning, is essential to ensure the efficient and reliable operation of booster pumps over time.

Overall, booster pumps are versatile and essential tools for increasing water pressure in various settings, helping to ensure adequate water supply and efficient water distribution for domestic, commercial, industrial, and agricultural applications.